Thermography / Infrared Analysis

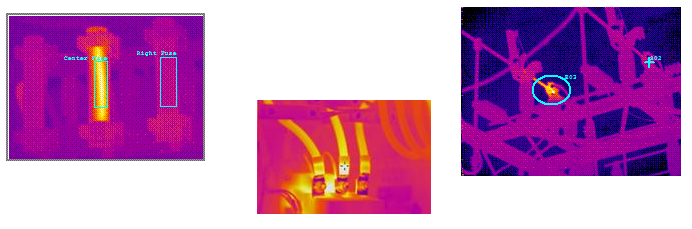

Infrared thermography is an excellent condition monitoring tool to reduce maintenance costs on mechanical and electrical equipment and detect developing problems. It allows for the monitoring of temperatures and thermal patterns while equipment is online and operating under load. Infrared has traditionally been used to monitor electrical equipment such as transmission lines, transformers, bus bars, isolation disconnects, motor control circuits, switchgear, relays and wiring. It has been proven time after time to readily identify reliability and safety concerns, and to provide excellent short-term ROI. For example, early detection of a single fault in a large transformer can easily save over one million dollars in equipment and maintenance costs.

Thermography can also be used on a wide variety of mechanical equipment including pumps, motors, bearings, pulleys, fans, and drives. Conditions such as misalignment, bearing preload / heating, filter clogging, and others, have been identified by M&B while performing thermography in conjunction with vibration analysis.

M&B Engineered Solutions can develop and implement an infrared monitoring program to help you increase your plant’s reliability. We can also train your personnel in survey and analysis techniques. We utilize the latest technology to develop comparative and absolute thermal images of electrical and mechanical equipment, and our staff is trained in analyzing data to accurately detect key temperature differences in electrical and mechanical equipment.

We can design, program, and staff a complete, cost-effective, thermography program to complement your PdM Program. We will provide the man-power, equipment & analysis expertise to provide you with a fully-functional program in a fraction of the time you would spend implementing, training, and staffing a program on your own.

Scanning routes can be established for your entire plant or a sub-set of electrical or mechanical machinery. Each route is designed and maintained by our professional field services staff with their integrity, knowledge and experience working for you every step of the route.

If you need assistance or have questions, please contact us.

Some specific machinery we have worked with include:

- Compressors

- Boiler & Process Fans

- Cooling tower fans

- Vertical & Horizontal Pumps

- Reciprocating Engines

- Gearboxes

- Pulverizers & Ball Mills

- Steam Turbines up to 1200 MW

- Gas Turbines, aero-derivative & industrial frame

- Generators and Exciters

- Induction & Synchronous Motors

- Variable Frequency Drives

- Vertical & Horizontal Pumps

- Hydro-Turbine Generators

- Reciprocating Engines