Machinery & Shaft Alignment

Machinery Shaft Alignment

Misalignment is one of the most common causes of rotating machinery failures, unplanned downtime, and industrial financial loss. How big of a problem is it? To quote John Piotrowski’s Shaft Alignment Handbook: “To get a picture of just how large a problem misalignment is, ask yourself how many pieces of rotating equipment are within a 100 mile radius of where you are right now. Statistically, over half of those machinery drives are excessively misaligned and will probably need to be shut down and repaired or replaced in the next 16 months.”

What causes misalignment? Almost anything! Poor installation technique; ‘soft foot’; flexible foundations; grout deterioration; pipe stress; thermal growth; torque; seal alignment; coupling wear; bearing wear, and more. All can directly affect the shaft alignment and create vibration and stress in the machines.

We are strong proponents of Precision Alignment – achieving the best possible shaft positioning for a given machine, based upon its design and intended use.

Precision alignment begins with an accurate Shaft Alignment, and is generally done with laser instrumentation. This is often all that is required on smaller machinery.

But on larger, more critical machines such as turbine generators, boiler feed pumps, and high speed compressors and gearboxes, we have repeatedly proven the value of measuring the machine movements that occur from offline-to-running conditions using Optical Measurements.

M&B engineers have extensive alignment measurement experience on nearly every class of machine. And we are one of the few vendors who can provide quality optical measurement services. These two specific areas are required to provide you with accurate operating machinery alignment data. We can identify how you can quickly correct existing problems caused by misalignment, and problems related to foundations, baseplates and piping. We can also provide your staff with specialized alignment training to improve their skills and increase your reliability.

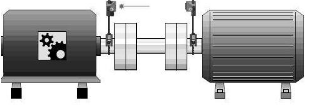

Shaft Alignment

The accurate alignment of machinery shafts is, in theory, a simple process – you move the machinery until the shaft centerlines are collinear. But in practice shaft alignment often proves to be frustrating without the proper tools, techniques, and experience. By utilizing laser instrumentation, dial indicators, and various techniques and tooling, M&B can accurately determine the alignment of any machinery and recommend corrective action for your staff.

- A typical alignment project might consist of:

- Inspect machinery baseplate & foundation

- Check shaft & coupling hub runout

- Measure pipe strain

- Measure / adjust for soft-foot

- Measurement the shaft alignment

- Determination how you should move the machinery

- Create alignment drawings for documentation

Whether the job calls for laser alignment, reverse-dial indicators, or rim & face measurements, M&B can quickly identify how you should move machinery to achieve precise alignment.

Machinery Installation & Setup

If you are installing new or refurbished machinery, or undergoing significant repairs, M&B engineers can assist you with a variety of tasks to get your work done on time and with a focus on ensuring long-term machinery reliability and operability.

Utilizing the optical tooling and techniques mentioned above, we can help you:

- Inspect the level condition of machinery soleplates within +/- 0.001″

- Inspect the level condition of machine casings within +/- 0.001″

- Monitor long-term elevations of installed foundations for settling

We also have standard construction / surveying instrumentation and experience, to assist you with:

- Foundation layout

- Marking / checking hold-down bolt locations before pouring

- Elevation studies

M&B engineers can assist you with nearly every phase of your machinery alignment. And as always, our focus is on your long term reliability and operability. If you have questions, or an application that is not mentioned above, please call us to discuss your needs.

Some specific machinery we have worked with include:

- Compressors

- Boiler & Process Fans

- Cooling tower fans

- Vertical & Horizontal Pumps

- Reciprocating Engines

- Gearboxes

- Pulverizers & Ball Mills

- Steam Turbines up to 1200 MW

- Gas Turbines, aero-derivative & industrial frame

- Generators and Exciters

- Induction & Synchronous Motors

- Variable Frequency Drives

- Vertical & Horizontal Pumps

- Hydro-Turbine Generators

- Reciprocating Engines